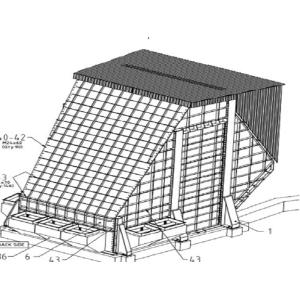

Mining Steel Hopper: Rugged Bulk Handling for Harsh Environments

Engineered to withstand extreme mining conditions, our steel hoppers are the backbone of efficient ore, aggregate, and mineral storage.

Key Specifications

- Material: High-abrasion-resistant steel (HARDOX 450/Q345B) with optional ceramic-lined interior for ultra-heavy loads.

- Design: Steep 60°-70° cone angles prevent bridging; reinforced crossbeams resist seismic vibrations and impact.

- Capacity: 10m³ to 500m³ configurations, compatible with crushers, conveyors, and automated sorting systems.

Mining-Specific Features

- Dust & Moisture Control: Integrated sealing systems and dehumidification ports comply with MSHA safety standards.

- Corrosion Defense: Triple-layer epoxy coating protects against acidic/alkaline slurry in gold/copper mines.

- Maintenance Access: Bolt-on wear plates and robotic inspection hatches minimize downtime.

Applications

- Open-pit or underground ore temporary storage

- Processing plant feed buffer

- Tailings management

| Product name | Steel Structure Hopper Used For Mining |

| Material | ASTM; EN; GB; |

| Surface | Painted; HDG |

OEM service available.

A dedicated team of fast response;

EN1090 & AISC & CWB & JIS Certificated Quality;

Full production line for customized products;

Close to Sea port, Convenient for visit and delivery;

150000M2 Manufacturing Area capable to take large volume

![]()

![]()